Introduction

The global silk market represents one of the most luxurious and historically significant segments of the textile industry. Renowned for its elegance, natural sheen, and softness, silk has long been a symbol of wealth, sophistication, and cultural heritage. In modern times, the market has evolved from traditional silk garments to a wide range of applications, including upholstery, cosmetics, and medical sutures. The silk market is gaining renewed attention due to the growing preference for sustainable, biodegradable, and premium-quality textiles.

In recent years, increasing consumer inclination toward eco-friendly fabrics, combined with the expansion of the luxury apparel sector, has driven the global silk market’s resurgence. Emerging economies such as China, India, and Thailand play a crucial role in silk production, while demand from regions like Europe and North America continues to rise. The market’s integration of innovative production methods and organic farming practices has further enhanced silk’s appeal among environmentally conscious consumers.

Stay ahead with crucial trends and expert analysis in the latest Silk Market report. Download now: https://www.databridgemarketresearch.com/reports/global-silk-market

Market Overview

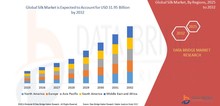

The global silk market has witnessed steady growth over the past decade, supported by rising disposable incomes and the global fashion industry’s expansion. According to industry estimates, the market is projected to grow at a healthy compound annual growth rate (CAGR) through 2032. China remains the world’s largest silk producer, accounting for nearly 70% of total global output, followed by India, which holds a significant share in both raw silk and finished silk production.

The rising demand for natural fibers, coupled with increased awareness of synthetic fabric pollution, has also bolstered silk’s position as a sustainable alternative. Moreover, advancements in sericulture technology and government initiatives to promote silk farming have significantly improved production efficiency and quality.

Regionally, Asia-Pacific dominates the market, driven by the presence of major silk-producing countries and growing domestic consumption. Europe and North America represent lucrative markets due to the rising popularity of luxury fashion brands and interior décor items made from silk. Meanwhile, Middle Eastern markets are witnessing increasing demand for silk-based textiles used in traditional attire and luxury products.

Key Market Drivers

Several factors contribute to the growing demand for silk globally:

Sustainable Fashion Movement – Consumers are increasingly choosing eco-friendly and biodegradable materials, positioning silk as a top choice among sustainable fabrics. Its natural origin, durability, and recyclability make it an ideal material for the ethical fashion industry.

Luxury and Premium Apparel Growth – The rising demand for high-end clothing and designer wear has directly influenced silk consumption. Major fashion houses prefer silk for its smooth texture and elegance, especially in products like gowns, scarves, ties, and lingerie.

Technological Advancements in Sericulture – Modern silk farming practices, including hybrid silkworm breeding and advanced reeling techniques, have improved yield and reduced costs. These innovations have strengthened the supply chain and enhanced product consistency.

Expanding Application Areas – Beyond textiles, silk is increasingly used in cosmetics, medical sutures, and biomaterials due to its biocompatibility and strength. This diversification opens new avenues for market expansion.

Government Support and Trade Initiatives – Nations like India and China actively support silk cultivation through subsidies, training programs, and export incentives, fostering sustainable growth across the industry.

Market Segmentation

The global silk market can be segmented based on type, application, and region:

By Type:

Mulberry Silk: The most common and luxurious type, accounting for the majority of global silk production.

Tasar (Tussar) Silk: Popular for its rich texture and natural gold sheen, often used in ethnic wear.

Eri Silk: Known for its warmth and sustainability, primarily used in winter clothing.

Muga Silk: A rare silk from India recognized for its durability and golden color.

By Application:

Textiles and Apparel: Dominates the market, with usage in clothing, accessories, and home décor.

Cosmetics and Personal Care: Silk proteins are increasingly used in skincare and haircare formulations for their moisturizing properties.

Medical and Industrial Applications: Used in sutures, tissue engineering, and biodegradable materials.

By Region:

Asia-Pacific: The largest producer and consumer, led by China, India, and Thailand.

Europe: High demand for luxury silk fashion and home furnishings.

North America: Growing adoption of sustainable textiles and premium apparel.

Middle East & Africa: Rising disposable incomes fueling luxury product demand.

Competitive Landscape

The silk market is moderately fragmented, featuring both global manufacturers and local producers. Key players focus on improving silk quality, expanding export capabilities, and innovating production technologies to maintain competitiveness.

Prominent companies operating in the market include Sichuan Nanchong Liuhe (Group) Corp., Anhui Silk Co. Ltd., Wensli Group Co. Ltd., Wujiang First Textile Co. Ltd., and Khadi & Village Industries Commission (KVIC). These organizations are investing in research and development to enhance silk fiber properties and introduce new blends catering to evolving consumer preferences.

Strategic collaborations between producers and fashion brands are also shaping the market. For example, partnerships between Asian silk producers and European luxury houses have strengthened global trade links and ensured supply chain stability. Additionally, companies are emphasizing traceability and organic certification to appeal to eco-conscious buyers.

Challenges and Restraints

Despite its growth, the silk market faces several challenges:

High Production Costs: Sericulture requires labor-intensive processes and specific climatic conditions, making silk production expensive compared to synthetic alternatives.

Environmental Vulnerability: Silk farming is sensitive to weather changes, pest infestations, and diseases affecting silkworms, leading to supply fluctuations.

Ethical Concerns: Traditional silk production involves killing silkworms during cocoon harvesting, raising ethical questions among vegan and cruelty-free consumers.

Competition from Synthetic Fibers: The widespread availability and affordability of synthetic fabrics such as polyester and nylon continue to pose strong competition.

Supply Chain Disruptions: Global events like the pandemic have exposed vulnerabilities in raw material supply and international trade logistics.

Future Outlook

The future of the global silk market appears promising, driven by sustainability trends, product innovation, and technological advancements. The integration of biotechnology into sericulture is expected to improve efficiency, reduce environmental impact, and enhance fiber quality. Innovations such as “peace silk” or “Ahimsa silk,” which allow silkworms to complete their life cycle, are gaining popularity among ethically minded consumers.

In addition, the growth of e-commerce platforms has expanded market reach, allowing small-scale producers to access international customers. The fusion of silk with other natural or synthetic fibers is also emerging as a trend to create hybrid fabrics offering strength, flexibility, and cost-effectiveness.

As the luxury and sustainable fashion sectors continue to evolve, silk will remain a preferred fabric due to its aesthetic appeal and environmental benefits. The increasing adoption of circular economy principles, coupled with consumer education about sustainable textiles, will further strengthen the market’s trajectory over the next decade.

Conclusion

The global silk market stands at the intersection of tradition and innovation. Its deep-rooted cultural significance, combined with modern sustainable practices, ensures a bright future for this timeless fabric. While challenges such as high costs and ethical production persist, advancements in technology and changing consumer preferences are paving the way for renewed growth.

Silk’s versatility across fashion, cosmetics, and biomedical applications makes it a valuable asset in the evolving textile landscape. As the world shifts toward sustainability, the silk market’s blend of luxury, eco-friendliness, and innovation positions it for continued success in the years ahead.

Frequently Asked Questions (FAQs)

What is the growth rate of the global silk market?

The global silk market is expected to grow at a steady compound annual growth rate (CAGR) during the forecast period, driven by rising demand for luxury and sustainable textiles.

Which region is expected to dominate the silk market in the future?

Asia-Pacific, particularly China and India, will continue to dominate silk production, while Europe and North America will lead in premium silk consumption.

Who are the leading players in the global silk market?

Key companies include Wensli Group Co. Ltd., Anhui Silk Co. Ltd., Sichuan Nanchong Liuhe (Group) Corp., and Wujiang First Textile Co. Ltd., among others.

What are the major challenges faced by the silk market?

High production costs, ethical concerns related to silkworm harvesting, and competition from synthetic fibers are some of the key challenges.

What are the future opportunities in the silk market?

Opportunities lie in sustainable silk production, peace silk innovations, hybrid fabrics, and expanding applications in cosmetics and healthcare sectors.

How is technology transforming silk production?

Technological advancements such as hybrid silkworm breeding, automated reeling, and eco-friendly dyeing methods are improving yield, quality, and sustainability.

Why is silk considered a sustainable fabric?

Silk is biodegradable, renewable, and long-lasting, making it an environmentally friendly choice compared to synthetic fibers that contribute to microplastic pollution.

Browse More Reports:

Global Infant Incubator Market

Global Infectious Mononucleosis Market

Global Inflatable Pillow Market

Global Injectable Nanomedicine Market

Global Intelligent Power Module Market

Global Intermodal Transportation Market

Global International Standards Organisation (ISO) Shipping Container Market

Global Interventional Cardiology and Peripheral Vascular Devices Market

Global Intrinsically Safe Equipment Market

Global Iris Retractor Market

Global Iron Ore Pellet Market

Global Irradiation Apparatus Market

Global Kallmann Syndrome Market

Global Keto-friendly Products Market

Global Kids Travel Bags Market

Global Kinase Inhibitors Market

Global Keyboard, Video and Mouse (KVM) Switch Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com